What Makes a Cooling Tower Work?

Let’s start with the most basic example of the principles behind a cooling tower; sweat. When the human body gets too hot and needs to shed excess heat, it begins to sweat. The sweat then evaporates and creates a cooling effect over the surface of the skin, which lowers the internal body temperature. Spreading water over a surface, exposing it to the air, causes the water to evaporate and produces a drop in temperature.

Not all air is created equal, however. Have you ever been somewhere with extremely high humidity, begun to sweat, and noticed that your sweat wasn’t evaporating? If you have, it is because not all air can accept the same amount of water vapor. There is only so much moisture that air can accept, so the process of cooling through water evaporation works best in very dry air. This is why the dry heat of the Arizona desert seems more bearable than the humid heat of the Florida summer, even though the desert’s temperature is actually higher.

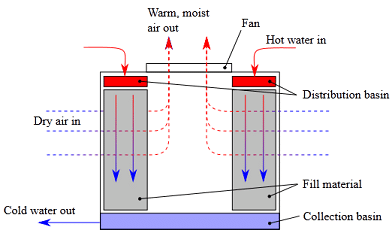

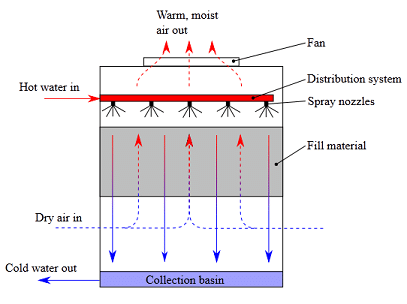

These ideas are what make a cooling tower work, but there is a lot more water to cool and evaporate in a cooling tower than the small amount of water the human body generates as sweat. Which is why a cooling tower adds in a few other factors to the equation; like, fans to replace air that is already saturated with moisture, devices to constantly circulate the water over the surface, the ability to continuously add water to replace evaporated water, and a heat source to make sure the runoff is heated. While cooling towers, their maintenance, and their construction are complicated topics the basic ideas behind how they work are no sweat.

The Specifics: Or, What You Need to Know To Select a Cooling Tower

To select a cooling tower that meets your needs there are a couple of specifics that you will need:

- Water flow rate

- Water inlet temperature

- Water outlet temperature

- Wet bulb temperature

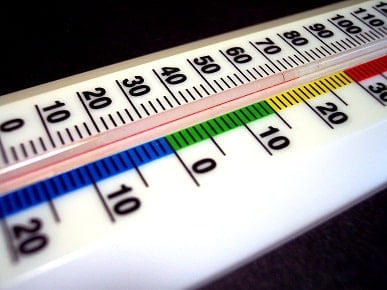

The most confusing of these specifics is the wet bulb temperature. The wet bulb temperature is used to determine the relative humidity, which changes throughout the day. The relative humidity is found by comparing the temperature of a dry thermometer with the temperature of a wet bulb thermometer. The wet bulb thermometer has water placed on its bulb, air is passed over it, the water evaporates, and the temperature is recorded. Most of the time the two thermometers will have different temperature readings, however, if the air is completely saturated with water the readings will be the same. When 100% relative humidity is reached the air can no longer accept water, the water on the bulb cannot evaporate, and the temperature will be the same as the dry bulb. So, the lower the wet bulb reading, the lower the humidity, the more moisture the air can accept, the more heat a cooling tower can be expected to reject.

The most confusing of these specifics is the wet bulb temperature. The wet bulb temperature is used to determine the relative humidity, which changes throughout the day. The relative humidity is found by comparing the temperature of a dry thermometer with the temperature of a wet bulb thermometer. The wet bulb thermometer has water placed on its bulb, air is passed over it, the water evaporates, and the temperature is recorded. Most of the time the two thermometers will have different temperature readings, however, if the air is completely saturated with water the readings will be the same. When 100% relative humidity is reached the air can no longer accept water, the water on the bulb cannot evaporate, and the temperature will be the same as the dry bulb. So, the lower the wet bulb reading, the lower the humidity, the more moisture the air can accept, the more heat a cooling tower can be expected to reject.

Many wet bulb readings are taken and recorded to determine the maximum wet bulb reading; the size of the cooling tower is determined by the max wet bulb reading. When sizing a cooling tower you want to err on the side of caution and size for the highest wet bulb reading because, your tower will then be oversized and the leaving water temperature will simply be lower.

How Fast Does a Cooling Tower Transfer Heat?

A cooling tower doesn’t actually control the rate of heat transfer; a cooling tower only transfers the heat it has been given. Heat transfer and evaporation rates do not vary, regardless of the size of the cooling tower. Wet bulb temperature, along with cooling tower size and flow rate, determine inlet and outlet water temperatures. However, the difference between inlet and outlet temperature is not determined by the cooling tower. For example, you could cool water from 90 to 80, or 100 to 90, but the 10 degree difference is not affected by the size of the tower. So, while you can’t change the rate of heat transfer, you can increase performance by increasing the surface area or booting the cfm.

Subscribe to the Cooling Towers Blog to get the next cooling tower fundamentals article, Cooling Tower Types.

The most confusing of these specifics is the wet bulb temperature. The wet bulb temperature is used to determine the relative humidity, which changes throughout the day. The relative humidity is found by comparing the temperature of a dry thermometer with the temperature of a wet bulb thermometer. The wet bulb thermometer has water placed on its bulb, air is passed over it, the water evaporates, and the temperature is recorded. Most of the time the two thermometers will have different temperature readings, however, if the air is completely saturated with water the readings will be the same. When 100% relative humidity is reached the air can no longer accept water, the water on the bulb cannot evaporate, and the temperature will be the same as the dry bulb. So, the lower the wet bulb reading, the lower the humidity, the more moisture the air can accept, the more heat a cooling tower can be expected to reject.

The most confusing of these specifics is the wet bulb temperature. The wet bulb temperature is used to determine the relative humidity, which changes throughout the day. The relative humidity is found by comparing the temperature of a dry thermometer with the temperature of a wet bulb thermometer. The wet bulb thermometer has water placed on its bulb, air is passed over it, the water evaporates, and the temperature is recorded. Most of the time the two thermometers will have different temperature readings, however, if the air is completely saturated with water the readings will be the same. When 100% relative humidity is reached the air can no longer accept water, the water on the bulb cannot evaporate, and the temperature will be the same as the dry bulb. So, the lower the wet bulb reading, the lower the humidity, the more moisture the air can accept, the more heat a cooling tower can be expected to reject.